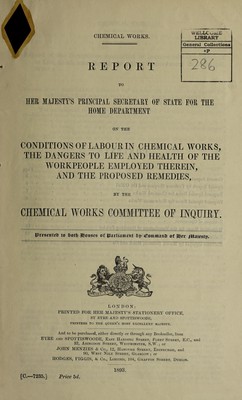

Report to Her Majesty's principal Secretary of State for the Home Department on the conditions of labour in chemical works, the dangers to life and health of the workpeople employed therein, and the proposed remedies / by the Chemical Works Committee of Inquiry.

- Home Office

- Date:

- 1893

Licence: Public Domain Mark

Credit: Report to Her Majesty's principal Secretary of State for the Home Department on the conditions of labour in chemical works, the dangers to life and health of the workpeople employed therein, and the proposed remedies / by the Chemical Works Committee of Inquiry. Source: Wellcome Collection.

5/40 (page 5)

![Hours of Labour. In the course of their inquiries the Committee have been impressed by the long hours of work which prevail in some departments of alkali works. In the vitriol department these amount, for burner men, to an actual average attendance at the works of 84 hours per week, whilst in the salt cake departments the men are accustomed to work two shifts of 13 and 11 hours respectively. The Committee would strongly advise the adoption of eight-hour shifts, wrhich have already been successfully tried in some departments at some of the works of the United Alkali Co., whilst at the works of Messrs. Brunner, Mond, and Co. eight-hour shifts prevail throughout. The Committee are indebted to Messrs. Brunner, Mond, and Co. for some very interesting facts as to the improvement of the men’s health since the eight-hour shifts were adopted. These figures, connected with their sick club, show that during a summer quarter in 1889, before the introduction of three shifts, the per-centage of those who received sick pay was 7*1, whilst during the same quarter of 1893, after the introduction, the per-centage was only 5T, or a reduction of 28-32. In 1889 the men attended by the doctor equalled 10-12 per cent., but in 1893 only 5-1 per cent., or a reduction of 49-6. Messrs. Brunner, Mond, and Co. wished to draw particular attention to the great reduction in those who received doctor’s attendance, which means stopping away from work one or two days without actually being laid up for a week, as in their club only men absent for a week receive sick pay. Messrs. Brunner, Mond, and Co., add that the cost of wages paid per ton of alkali produced by them is now no more than it was four years ago, in spite of the fact that the men employed on shift work are paid the same wages for eight hours as they were formerly paid for twelve. This improvement they attribute partly to improvements in the apparatus used, effected at considerable cost, and partly to the increased efficiency of the men due to their better health and spirits. Bichromate of Potash or Soda. This manufacture is practically in the hands of three firms at Glasgow, Rutherglen, and Falkirk, all of which works were visited by the Committee. The Committee found that almost all the men working where dust was prevalent, more especially between the furnaces and the dissolving tanks, had either perforation of the septum of the nose, or had lost the septum altogether. Many of those employed suffer also from what are technically called “ Chrome holes ”' on hands and arms. These are caused by dust or liquor acting on broken skin, or by the handling of crystals. The process is as follows : Chrome ore is ground by machinery. A great deal of dust prevails in the grinding rooms, and the use of some form of respirator is advisable, though this dust is only harmful mechanically. The ground ore is put into hot]furnaces with carbonate of potash, or soda, and lime, and comes out in form of cake. This cake is often placed on the floor and allowed to cool before being put into the tanks. When cool, a great deal of deleterious dust arises from throwing it into the tanks. This harmful dust might to a great extent, in the opinion of the Committee, be obviated by throwing the cake into the tanks at once, instead of leaving it to cool and form dust. The cake when placed in the tanks is treated with water and the chromate of soda or potash dissolved out. The solution of yellow chromate is then treated with sulphuric acid, and bichromate is thus formed. This solution is evaporated, and the crystals are obtained. The Committee strongly recommend the use of respirators where any dust arises, and the use of gloves where crystals have to be handled. Sufficient suitable lavatory accommodation and appliances should also be provided. The Committee are of opinion that the due observance of cleanliness on the part of the operatives would largely conduce to the prevention of the evils referred to. Chemical Works in General. As regards the question as to how far the injurious effects depend upon the age and sex of the operatives, the Committee find that no females are employed in alkali works, and but few boys under 18 years, except in cooperages, plumbers’ shops, box-making, &c. Moreover, their inquiries do not lead them to suppose that exceptional mortality, apart from accidents, exists in them. a 3](https://iiif.wellcomecollection.org/image/b30558050_0005.jp2/full/800%2C/0/default.jpg)