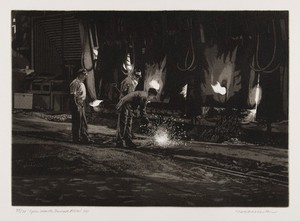

This is one in a set of four aquatints commissioned by Mr William Church when working in his first works management post for British Steel at Bilston, Staffs. He had been aware of the need for good pictures that captured the atmosphere of the steelworks. As a collector of etchings he was in touch with people who suggested approaching Harry N Eccleston, an accomplished printmaker and a Bilston native who had studied at Bilston School of Art. Eccleston had relatives who worked in the steelworks and had produced pictures of cranes and locomotives seen from the outside, but had not been allowed inside the works. Eccleston was, at that time, head of design at the Bank of England Print Works and was responsible for the series of notes including the Waterloo five pound note

On receipt of the commission, Eccleston made preparatory studies for the aquatints in the form of photographs, watercolours and gouaches. The work on the four plates took place over some ten years. Editions of 70 were made; probably about half of the impressions were bought by members of the steelworks staff at cost